SLUDGE DEWATERING PLANTS

REŠETILOVS develops and offers

factory made complete sludge dewatering plants

and separate components for sludge processing.

.png)

RANGE OF PRODUCTS

- sludge dewatering plants

- equipment for sludge dewatering in filtration bags

- flocculant preparation units

- static mixers

- ejectors

- electric and manual stirrers

- screw conveyors

- control panels.

- High sludge dewatering efficiency;

- Compact footprint and mobility due to package-modular design;

- Low expenses for foundations of equipment due to small area for it placement;

- Minimal on-site mounting works and no expenses for technological external network due to ready-to-use technological solutions with factory made equipment;

- Low operational expenses due to minimal electrical power consumption and process full mechanization and automation;

- Long-life due to stainless steel use;

- Ecological safety due to complete processing and safe handling, storage and transfer arrangement to the following waste utilization from WWTP.

Sludge dewatering plant

Sludge dewatering plant

with filtration bags

Models range from 12 up to 96 kg by dry solids a day.

Functionality:

- sludge dewatering from domestic and industrial wastewater treatment plants.

Design:

- module frame system;

- containerized system.

Sludge dewatering plantwith multidisc screw conveyor

Sludge dewatering plantwith multidisc screw conveyor

Models range from 70 up to 420 kg by dry solids a day.

Functionality:

- sludge dewatering from domestic and industrial wastewater treatment plants.

Design:

- module frame system;

- containerized system.

Sludge dewatering plantwith belt filter press

Sludge dewatering plantwith belt filter press

Models range from 500 up to 1400 kg by dry solids a day.

Functionality:

- sludge dewatering from domestic and industrial wastewater treatment plants.

Design:

- module frame system;

- containerized system.

Flocculant preparation and dosing unit

Functionality:

- Preparation of flocculant solution, flocculant storage and dosing.

Static mixers

Functionality:

- Sludge and flocculant mixing.

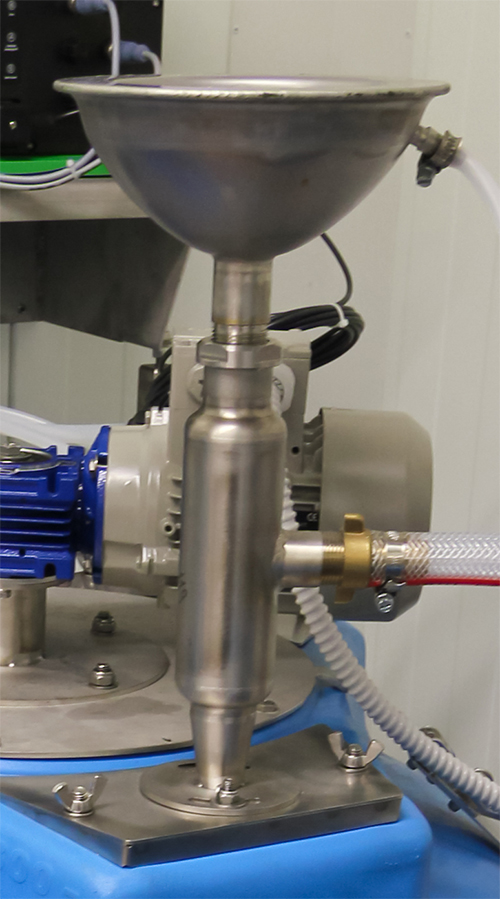

Ejectors

Functionality:

- Dry flocculant proper mixing with water during flocculant solution preparation.

Electrical and manual stirrers

Functionality:

- Mixing of flocculant solution.

Screw conveyors

Functionality:

- Transportation of dewatered sludge.

Power supply and control panels

Functionality:

- Electricity supply. Sludge dewatering components can be equipped with power supply and control panels.

Sludge dewatering equipment can be produced for transportation in following ways:

- for road transportation by truck,

- for transportation inside standard closed sea container 20' DC (20'x8'x8,6'') or 40' HC (40'x8'x9,6'').